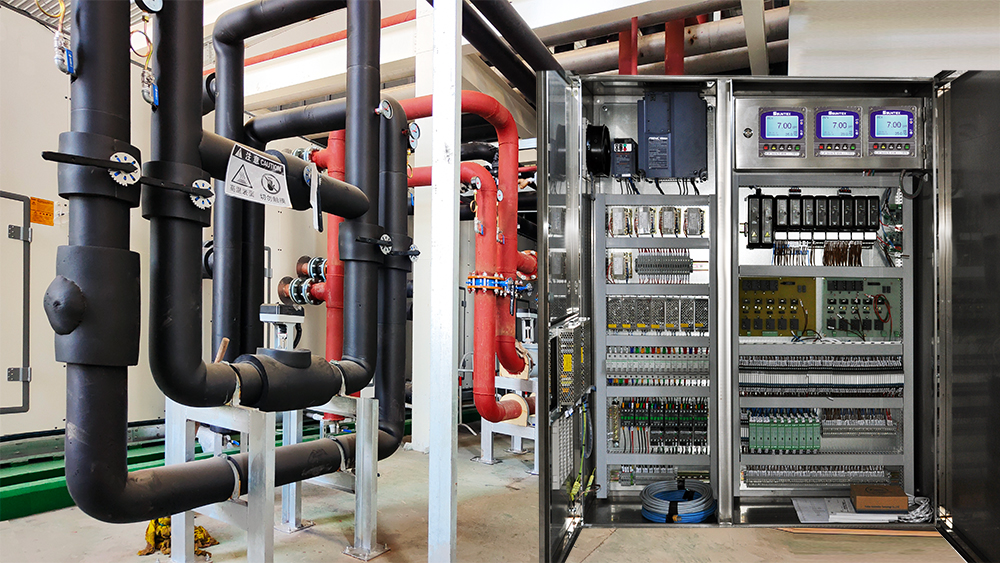

The installation and debugging of the sewage treatment control system was carried out on site by professional electricians dispatched by the Aixun Automation team. The installation of the entire control system project was completed based on the actual situation on site.

The electrical control cabinet for the dust removal system in the silicon industry (No. 1 dust removal system, Room 4) is independently designed by Aixun Company. Our company will dispatch professional electricians to the site for installation guidance. Debugging is carried out by professional electrical engineers dispatched by Aixun Company to conduct on-site debugging of automated operation.

On site installation and commissioning of sewage treatment control system. According to customer requirements, Aixun Company has installed a sewage treatment control cabinet on site and also completed the installation of the on-site control box, preparing to enter the debugging phase.

This sewage treatment control system adopts Emerson PLC and is designed to be controlled by Chint low-voltage electrical appliances. The frequency converter adopts INVT frequency converter. The entire control system has the function of central control manual automatic control and supports upper computer control.

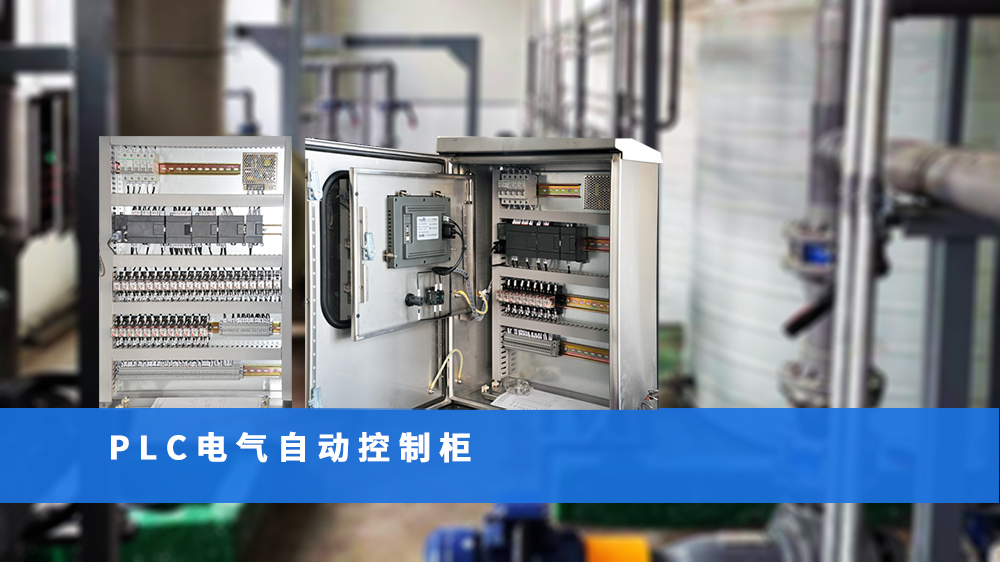

The DCS control cabinet for the fully automatic dosing device in the pharmaceutical factory adopts a stainless steel cabinet, equipped with Thai PH instruments, Fuji frequency converters, and Emerson DeltaV DCS system, achieving manual operation/automatic/DCS remote control mode.

The PLC automatic control cabinet for the bacterial culture tank in the pharmaceutical factory adopts a stainless steel cabinet, equipped with E+H instruments, Nideco frequency converter, and Siemens 1500PLC to achieve dynamic operation/automatic/DCS remote control mode.

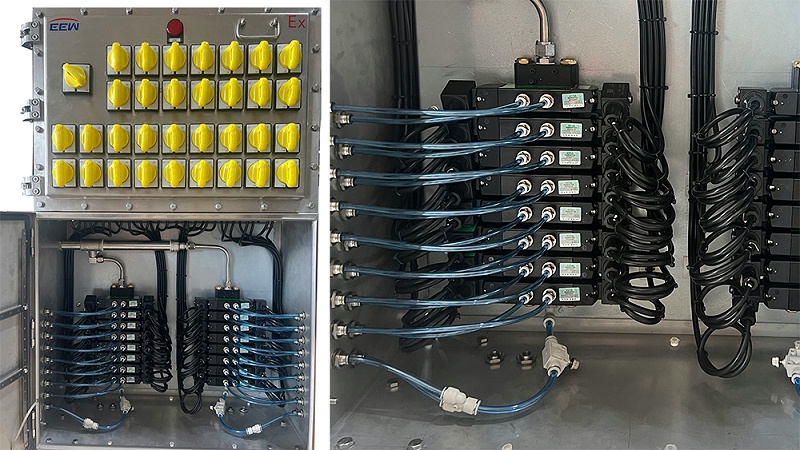

Each solenoid valve position in the ASCO separate shut-off solenoid valve box manifold has a separate shut-off and centralized exhaust function. In the event of a malfunction in one solenoid valve, it can quickly switch to the backup valve without affecting other working solenoid valves, facilitating maintenance and debugging, reducing subsequent on-site maintenance time and costs, and greatly improving work efficiency, The electromagnetic valve box is an integrated electromagnetic valve group formed by installing a single electromagnetic valve on the manifold board, and then connecting the coil of the electromagnetic valve to the terminal. The electromagnetic valve box is centrally controlled by a remote PLC control cabinet or DCS control cabinet. The advantage of the electromagnetic valve box is that it is easy to maintain, reduces the cost of on-site air and cable, and is aesthetically pleasing.

The valve island control cabinet of the sewage treatment plant adopts a stainless steel cabinet, Schneider low-voltage electrical (circuit breaker), switch power supply, FESTO (VTSA series valve island, filter, threading joint, PU nylon pipe) to achieve on-site valve plate manual button control, and DCS upper computer communication control.

The bus valve island box adopts clear text display and intuitive button software, and supports various communication protocols. By using FESTO bus valve island boxes, customers can save costs and reduce outgoing lines. Simple settings and visual operation can be performed, and maintenance is simple.

The dual electric control solenoid valve box in the power industry is equipped with a carbon steel spray cabinet shell and a customized integrated joint. The ASCO dual electric control 2-position 5-way solenoid valve is integrated for control, which is clean and beautiful. At the same time, it can achieve local button manual button control and DCS remote control.

The dual door automatic control dual electric control solenoid valve box in the power industry adopts a carbon steel spray cabinet shell and explosion-proof terminal box, equipped with customized integrated joints. The ASCO explosion-proof solenoid valve integrated control is clean and beautiful, and can also achieve local button manual button control and DCS remote control.

The PLC automatic control cabinet of the sound wave ash cleaning system adopts a carbon steel spray cabinet, Schneider low-voltage electrical (circuit breaker), switch power supply, touch screen, Siemens SMART200 PLC to achieve on-site valve plate manual button control, and DCS upper computer communication control.

The high-temperature filtration device control cabinet adopts stainless steel cabinet, Schneider low-voltage electrical (circuit breaker), switch power supply, touch screen, Siemens SMART200 PLC to achieve on-site valve plate manual button control, and DCS upper computer communication control.

The automation control cabinet, PLC control cabinet, and MCC cabinet control system use Schneider low-voltage electrical and Weitu cabinets to concentrate the on-site motors and communicate with DCS through DP bus protocol for control.

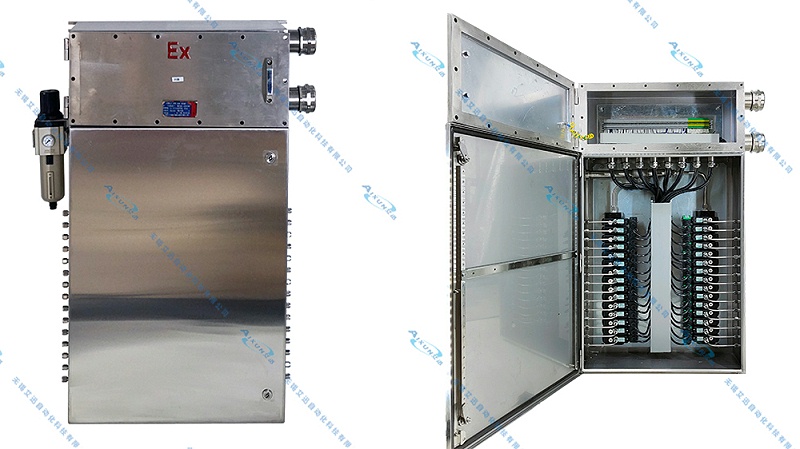

ASCO solenoid valve - explosion-proof solenoid valve control box with remote DCS upper computer control and local manual control, explosion-proof terminal box and stainless steel box combined, used in paper mills, power plants, petrochemical, biopharmaceutical and other industries.

ASCO solenoid valve - explosion-proof solenoid valve control box with remote DCS upper computer control and local manual control, explosion-proof terminal box and stainless steel box combined, used in paper mills, power plants, petrochemical, biopharmaceutical and other industries.

In August 2019, the person in charge of an environmental protection company in Zhangjiagang, Jiangsu Province learned that Wuxi Aixun is an automation technology Co., LTD., through peer introduction, and said that a set of VOC exhaust gas treatment control cabinet needs to be customized. Wuxi AiXun provides a set of more perfect technical solutions. The two sides reached the initial cooperation intention of VOC exhaust gas treatment control system and signed a contract, Wuxi AiXun is responsible for the complete control system and on-site service.

In June 2020, the person in charge of an electricity project in Shandong learned about Wuxi AiXun through the introduction of old customers, and Wuxi Ixun provided several sets of more perfect technical solutions after many technical exchanges and field visits. The customer reached a preliminary cooperation intention and signed a contract with Wuxi Aixun for the bus valve island control system after comparison and consideration in many aspects. Wuxi Aixun is responsible for the complete control system and on-site service.

Aixun's reliable service process satisfies the design of solenoid valve control cabinet of cooperative customers. Cooperative customers are very satisfied with Aixun's reliable service team, automatic industrial control parts procurement service, automatic industrial control scheme design, manufacturing production, installation and commissioning, and after-sales service. Aixun has been recognized by the responsible person of cooperative customers, and the cooperation is very successful.

The project is a central air-conditioning control system of a subsidiary of a domestic photovoltaic giant, the system uses Siemens S7-400CPU as the main controller, 17pcs ET200SP are slave station of IO, The monitoring software of upper computer is WinCC7.5.