The project is a central air-conditioning control system of a subsidiary of a domestic photovoltaic giant, the system uses Siemens S7-400CPU as the main controller, 17pcs ET200SP are slave station of IO, The monitoring software of upper computer is WinCC7.5.

The nearest distance between each IO substation to main controlling PLC about 50m and the longest distance about 300m, normally, the network cable, GPRS internet of things and fiber will be used for date communication form each IO slave station to main controlling PLC

Fiber ring network transmission becomes a better choice because of its higher security, transmission rate and long transmission distance.

Each fiber terminal box is connected together to form a closed ring network by fiber, and the switcher is connected with the ET200SP slave station through the network cable. When any fiber in the ring network is break off, it has no effect on the data received by the main control CPU, there will not occurred the situation of communication broken and data loss; And fiber transmission is relatively fast, the transmission distance can be up to 20km.

1. Fiber channel switch integrated optical module unit, single module and single fiber, fiber interface SC (blue big square terminal), central wavelength 1310/1550nm; the transmission distance is 20KM.

2. The switch end of the access ring switcher is jumper fiber, from the fiber terminal box out

3. Fiber ring network system structure chart

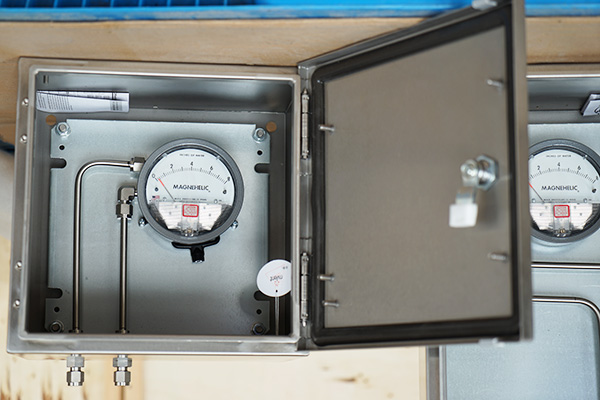

4. Hardware layout in cabinet (portion)

5. Upper computer monitoring menu (portion)