To prevent the pollution of the surrounding environment caused by the wastewater generated by the beverage factory, it is necessary to treat the wastewater before discharging it. Therefore, a highly automated sewage treatment PLC control cabinet is required.

PLC control cabinet - capable of achieving equipment automation and process automation control, realizing network functions, stable performance, scalability, strong anti-interference and other characteristics, is the core and soul of modern industry. PLC control cabinets, frequency conversion cabinets, etc. can be customized according to user needs to meet user requirements, and can be paired with human-machine interface touch screens to achieve easy work. The device can also transmit data with communication protocols such as modbus and profibus on the DCS bus upper computer; Control and monitoring implemented by industrial computers, Ethernet, etc.

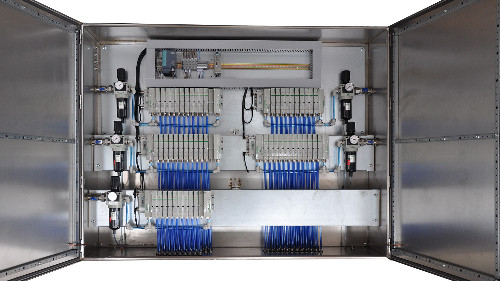

The PLC automatic control system cabinet includes five parts: rack or chassis, power module, processor (CPU), input/output module, and communication interface module. The power module is used to provide the required power for the entire PLC system. It converts available AC power into DC power required by the CPU and I/O modules. PLCs typically operate on a 24V DC power supply. Few PLCs use isolated power sources. The CPU module CPU module has processors, drivers, and applications. Memory is used to store programs and data. The CPU is the brain of a PLC with an octagonal or hexagonal microprocessor. As other electrical components based on microprocessors, cables used to connect other devices. Input/Output Module - Input devices can be start and stop buttons, switches, etc., and output devices can be electric heaters, valves, relays, etc. Digital modules facilitate the interface between input and output devices and microprocessors.Beverage factories are one of the fastest-growing industries in China's food industry. The varieties also include fruit and vegetable beverages, protein drinks, tea drinks, coffee drinks, plant drinks, and other types. Along with the high degree of automation in the production line of beverage factories, the wastewater generated and its pollution to the environment are gradually being taken seriously by people. Beverage production is a typical intermittent production, and the products produced are unstable, which brings certain difficulties to the treatment of wastewater. To prevent the pollution of the surrounding environment caused by the wastewater generated by the beverage factory, it is necessary to treat the wastewater before discharging it. Therefore, a highly automated sewage treatment control system is needed.

Our technical personnel develop a plan based on the process flow diagram and technical requirements provided by the design party. This plan mainly consists of a distribution cabinet, MCC cabinet, PLC cabinet, local work button box, and upper computer. Due to the short project duration, which requires meeting both delivery time and technical requirements, technology has higher requirements for selection and design. Our company has multiple practical cases similar to beverage factories, and our technical personnel are proficient in product selection. We also have long-term cooperation with suppliers and stocking capabilities. After cooperation with multiple departments in our company, we have designed a solution. The set of wastewater treatment PLC control cabinet for the beverage factory was completed on time and with good quality.

Wuxi Aixun Automation Technology Co., Ltd. is engaged in automation control design and production processing. For a long time, AIXUN Automation has been in line with the concept of "listening to customer needs, thinking solutions together with customers, and trying to solve problems for customers", serving customers in various industries, in accordance with the modern enterprise management mechanism "honesty as the fundamental, quality as the focus, customer-centric".

Aixun Automation is looking forward to the support of new and old customers as always! Sincerely hope to work with you hand in hand, common development