In 2019, Aixun Automation designed and drafted an electrical automation control system based on customer requirements and the automotive industry process control requirements and BOM list. The system has on-site manual mode control and remote upper computer control. The installation and commissioning were not completed in 2019 and were handed over to the owner.

The manufacturer of the electrical automation control system for this equipment is Wuxi Aixun Automation, which has developed an automation control system for waste gas equipment. The hardware of the VOC equipment PLC control cabinet can operate with Rockwell AB, Siemens, GE and other medium and large PLCs as control hardware, and different control system schemes can be customized according to different waste gas treatment equipment.

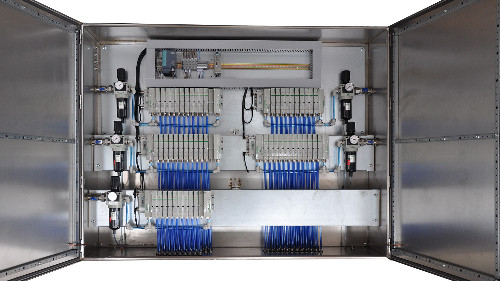

The electrical automation control system adopts a multi-channel flue gas tower mode, and the absorption process adopts a spray washing tower. The NaOH alkaline liquid stored at the bottom of the tower is sent to the spray layer through a circulating water pump, atomized into micro droplets through a nozzle, and chemically reacts with the acid mist gas in the flue gas to produce acid mist sodium. It falls into the slurry tank and continues to react. The liquid that crystallizes to a certain concentration is discharged into the wastewater treatment system through an electric valve after passing through the circulating water pump.

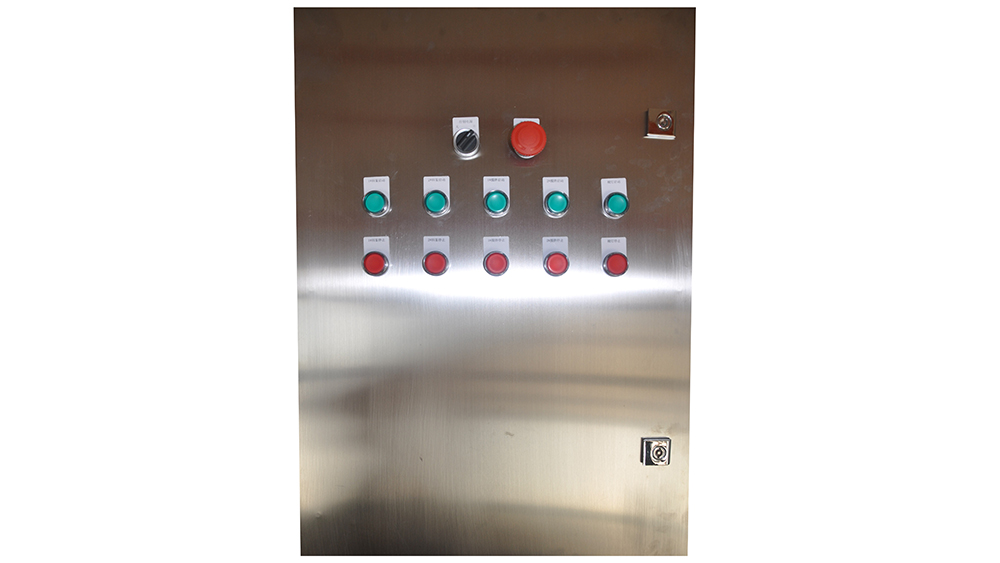

The electrical automation control system consists of a lower level PLC. It has functions such as data collection, operation control, control output, control regulation, equipment operation status monitoring, fault alarm, real-time data processing and display, data management, graphic display, remote communication, etc.

Scheme description:

The owner's DCS system uses Rockwell AB's 1756 PLC as the main controller, and requires our lower computer control system to use AB's 1769 series PLC. The communication between DCS and PLC is in the form of producer consumer labels. The communication architecture is based on Ethernet. Analog input and output signals are fully isolated, using Weidmuller's signal isolator. Four 160KW frequency converters adopt ABB's ACS880 series. The copper busbar of the main distribution cabinet is protected with heat shrink tubing and glass panels. The cabinet of the entire electrical automation control system is made of SUS304 stainless steel, and the cooling system is equipped with Weitu's cooling air conditioning.

Wuxi Aixun Automation Technology Co., Ltd. is engaged in automation control design and production processing. For a long time, AIXUN Automation has been in line with the concept of "listening to customer needs, thinking solutions together with customers, and trying to solve problems for customers", serving customers in various industries, in accordance with the modern enterprise management mechanism "honesty as the fundamental, quality as the focus, customer-centric".

Aixun Automation is looking forward to the support of new and old customers as always! Sincerely hope to work with you hand in hand, common development